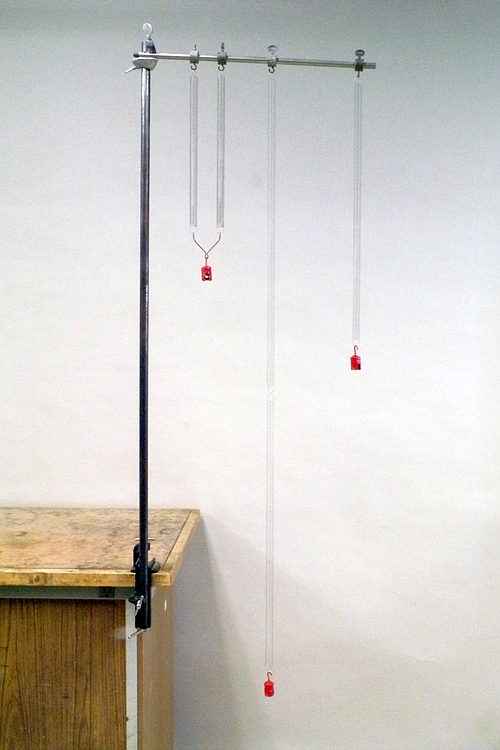

All three masses in the photograph above have the same mass (50 g), and all the springs are identical (free length 7.5 cm (not including loops) and k ≈ 1 N/m). At right, a single spring hangs from a hook, with a mass hanging from its bottom end. In the middle are two springs, one hanging from the bottom of the other, with a mass hanging from the free end of the bottom spring. At left are two springs hung side by side, their bottom ends connected with a wire, and a mass hanging from that. With this demonstration you can show the relationship of the effective force constant of each two-spring system to the force constant of the single spring. This provides a good illustration of the relationship between the dimensions of a material and how much it deforms when placed under load (vide infra).

When you extend or compress a spring, the force that the spring exerts in response is F = -kx, where x is the distance by which you extend or compress the spring, and k is the force constant, which is a measure of the stiffness of the spring. This is Hooke’s Law. In order to support a particular mass, then, the spring must extend or compress until the force it exerts balances the force that gravity exerts on the mass, mg. The 50-g mass hanging from the single spring at right, then, extends the spring by x = mg/k, or (0.050 kg)(9.81 m/s2)/(1 N/m) = 0.49 m, or 49 cm.

The two springs in the middle are hung in series; one spring hangs from a hook, the second spring hangs from the bottom of the first spring, and the mass hangs from the bottom of the second spring. If we ignore the mass of the springs, then each spring has a force of (0.50 kg)(9.81 m/s2) = 0.49 N pulling down on its lower end. Each spring, then, extends by about 49 cm, but since they are connected end to end, the overall extension of the two-spring system is twice this, or about 0.98 m. F = keff(2x), and keff = k/2, where keff is the effective force constant of the two springs hung in series. Put more generally, the distances by which the two springs are extended are x1 = F/k1 and x2 = F/k2, so x1 + x2 = F(1/k1 + 1/k2), and 1/keff = (1/k1 + 1/k2). If we hung additional springs, the force constants would add in similar fashion (reciprocally). Since each spring in this apparatus weighs just over 11 g, the bottom spring by itself extends the top spring by about 20 percent of the distance by which the 50-g mass extends it, so the extension of the top spring is somewhat greater than that of the bottom spring.

The two springs at left are hung in parallel; at the top, both springs are hung from the support rod, and at the bottom, the ends are tied together by a wire hanger, from which the mass is suspended. Each spring thus bears half the load, or about 0.24 N. The extension, then, for both springs is x = (0.24 N)/(1 N/m), or 24 cm, half the extension for the single spring. Allowing for the free length of the springs, we see that the extension for the springs at left is about half that for the single spring at right. Since the extension is the same for both springs, we can write F = x(k1 + k2), and keff = (k1 + k2) = 2 N/m. Since the force constant is the same for both springs, the mass as it is hung in this demonstration extends both springs equally. If the springs had different force constants, the hanger could rotate so that the extension would be different for each spring. We could, however, prevent the hanger from rotating, either by fixing it to a bar that rode along two vertical rails (with low-friction linear bearings), or by making the hanger so that we could set the mass off center. If we did this, then even if the springs had different force constants, the extension would be the same for both of them, and the equation above would hold. The effective force constant would be the sum of the individual force constants, and this would be true for any number of springs we decided to hang in parallel.

When a stress is applied to a piece of material, the material undergoes a corresponding deformation, or strain. Under a tensile stress, the material stretches, and under a compressive stress, it contracts. As long as the deformation is not great enough to take the material past its elastic limit, it is proportional to the applied force; the material obeys Hooke’s Law. Strain is expressed as a proportion to the original length of the material; strain = (l - l0)/l0, or Δl/l0, where l0 is the original length of the material, and l is the length of the material under stress. The ratio of the applied force per unit area, to the deformation, the stress divided by the strain, is (F/A)/(Δl/l0). This quantity is called the Young’s modulus of the material, and is usually denoted Y. If we take Y = (F/A)/(Δl/l0) and rearrange it, we can write Hooke’s Law as F = (YA/l0)Δl, where k = (YA/l0) and x = Δl. Here we are assuming that the applied force is perpendicular to the cross-sectional area of the material; the stress a normal stress (as opposed to a shear stress; see demonstrations 32.24 -- Shearing of foam logs, 32.27 -- Book shear and 32.30 -- Bending boards).

We see from the analysis of the mass-spring systems above, and the expression for k as (YA/l0), that arranging two or more springs in series is similar to increasing the length of a piece of material to be placed under load, and arranging two or more springs in parallel is similar to increasing the cross-sectional area of a piece of material to be placed under load.

References:

1) Sears, Francis Weston and Zemansky, Mark W. College Physics, Third Edition (Reading, Massachussetts: Addison-Wesley Publishing Company, Inc., 1960), pp. 205-14.

2) Halliday, David and Resnick, Robert. Physics, Part One, Third Edition (New York: John Wiley and Sons, 1978), p.303.

3) http://hyperphysics.phy-astr.gsu.edu/hbase/permot3.html#c2 and related links.