Place a bimetallic strip over the flame. The two metals in the strip expand at different rates, which causes the strip to curl.

In front of the Méker burner in the photograph above, are two bimetallic strips. These are pairs of metal strips bonded together face to face, to make a single strip. The one in the blond handle is a 0.005″-thick strip of steel bonded to a 0.010″-thick strip of brass. In this bimetallic strip, it is possible to see the two layers. The composition of the bimetallic strip in the black handle is not specified, and the two layers are bonded in such a way that they appear as one.

All materials undergo a change in dimension as the temperature changes. For solids, this change occurs along each of the three spatial axes, and along any given axis is described by the equation

ΔL = αL0 ΔT

where α (= ΔL/(L0 ΔT)) is the coefficient of linear expansion. Since the units of length cancel, α has the units of reciprocal °C (or F). It can be useful to rearrange the equation above as

L = L0(1 + α ΔT)

For most materials, α is positive; the material expands with increasing temperature. One notable exception comprises certain types of rubber (see demonstration 48.25 -- Rubber band shrinks when heated).

As described above, a bimetallic strip is a device that consists of two strips, each of a different metal, bonded to each other along one face. Different metals have different coefficients of linear expansion. The table below gives some examples. (These values are from The Engineering Toolbox. Note that ALLVAR, the sixth entry from the top, has a coefficient of linear expansion of -30 × 10 -6 m/(m°C); it contracts when heated. It is made by ALLVAR Alloys.)

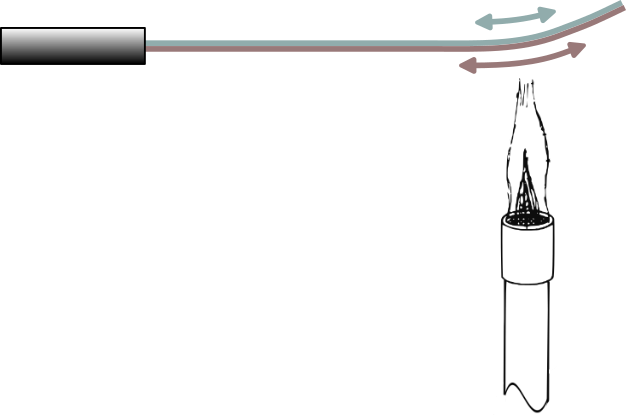

Material α (10-6 °C-1) Aluminum 21-24 Brass 18-19 Copper 16-16.7 Magnesium 25-26.9 Nickel 13.0 Platinum 21-24 Steel 10.8-12.5 Since the two metals in the bimetallic strip have different coefficients of expansion, as the temperature changes they expand or contract at different rates. This creates shear forces along the plane at which the two metals are bonded, which causes the strip to bend. This is illustrated in the figure below, which shows a bimetallic strip whose bottom layer has a greater coefficient of expansion than that of the top layer (like the brass/steel bimetallic strip with the brass on the bottom), being heated at one spot by a flame. The two double arrows illustrate the differential expansion that results.

The differential expansion that occurs where the strip is heated, causes it to curl upward. (If the strip faced the other way, with the brown layer on top, it would curl downward.) If the whole strip were heated, it would curl over its entire length. This demonstration clearly shows that the displacement of the end of the strip when it curls, is much greater than the change in length of either layer (or the difference in length that results from the differential expansion). This makes the bimetallic strip useful in thermometers and thermostats.

In thermometers that use bimetallic strips, the strip is usually wound into a spiral. The outside end of the strip is fixed, and the end near the center is attached to the shaft on which a pointer sits. As the temperature changes, the changing curvature of the strip causes the shaft to rotate, which moves the pointer along a scale that shows the temperature. Because the conversion of the change in curvature of the strip to rotatory motion of the shaft is somewhat inefficient, these thermometers are not particularly accurate.

In thermostats, the bimetallic strip is usually formed into a spiral, one end of which is connected to the mechanism by which one adjusts the temperature set point. This end is also connected to a power source. The other end of the strip has a straight section that either sits near a contact that is connected to the control board that runs the furnace, or has mounted on it a mercury switch, one end of which is connected to power, and the other end of which goes to the control board. When the temperature of the house falls sufficiently below the set point, the bimetallic strip either touches the contact to close the circuit, or tilts the mercury switch until it closes the circuit. When the temperature of the house again reaches the set point, the bimetallic strip pulls away from the contact (or tilts the mercury switch), thus opening the circuit and turning off the furnace. (To avoid overshooting the set point, a short wire, set beneath the coiled bimetallic strip, is connected in series with the contact that goes to the furnace control board. This wire is called an anticipator, and it gently heats the bimetallic strip while the furnace is running, so that the thermostat turns the furnace off a little bit before the set point is reached.) In systems in which the thermostat operates both a furnace and a cooling system, the moving end of the bimetallic strip sits between two contacts, one to turn on the furnace, and one to turn on the cooling system. If the house becomes too hot, the bimetallic strip touches the contact that closes the circuit that turns the cooling system on. When the house has cooled to the set point, the bimetallic strip pulls away from the contact and turns the cooling system off. Some thermostats use two bimetallic strips, one to operate the furnace, and one to operate the cooling system.

Another type of thermostat that uses a bimetallic element is a thermal snap switch (or snap switch, disc thermostat, or snap action thermostat). This is a device that has inside it a switch that is operated by a bimetallic disc. These switches typically are made to open when they are heated to a particular temperature, and then to close again when they cool below a temperature that is somewhat lower than the temperature at which they open. When the switch is heated to its rated upper temperature, the bimetallic disc flips inside out (goes from convex to concave), and opens the switch. When it cools to its rated lower temperature, the disc flips back to its original shape and closes the switch. Commonly used in such things as coffee makers, electric kettles and oil diffusion pumps, these are connected in series with the heater, so that when the apparatus reaches the desired (or maximum allowable) temperature, the switch opens, cutting off the current through the heater. The type of switch described above is referred to as normally closed. These switches are also available in a normally open configuration, in which when the switch reaches its rated temperature, it closes, and when it cools below its rated temperature, it opens again. Such a switch could be used, for example, to operate a cooling fan to prevent something from overheating.

References:

1) Sears, Francis Weston and Zemansky, Mark W. College Physics, Third Edition (Reading, Massachusetts: Addison-Wesley Publishing Company, Inc., 1960), pp. 296 - 298.